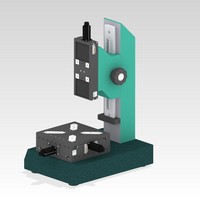

Specially for the OEM market designed stands simplify the application of our cross and linear stages for custom solutions.

The stands have a high accuracy regarding flatness and angularity of the reference planes.

Granite, aluminium or iron cast is used as base material.

In combination with the cross and linear stages, high system requirements are fulfilled.

To combine and to mount the positioning systems, a large variety of adaptor plates and angles is available.

The modular concept has no limits for individual applications.

![]() Positioning Systems brochure download...

Positioning Systems brochure download...

Stands

• stable design using granite, cast steel or aluminium for high torsional stiffness

• precise locating surfaces for axes with high positioning accuracy

| Stand | X/Y Stroke (mm) Z Stroke (mm) |

Z-Drive | Base body Column |

System Diagram |

| MS2-P |

25 x 25 - 100 x 50 25 300 - 500 |

motorized hand driven (coarse adjustment with clamping or gear rack) |

granite aluminium profile |

|

| WM2 |

25 x 25 - 100 x 50 25 50 - 100 |

motorized hand driven (coarse adjustment with clamping) |

cast steel |

|

| MS2-110 |

50 x 50 - 100 x 50 50 - 170 |

motorized | granite aluminium |

|

| VM3 |

50 x 50 - 100 x 50 150 150 |

motorized hand driven |

cast aluminium aluminium profile |

|

| MS3 |

100 x 100 - 150 x 100 50 - 170 150 |

motorized hand driven |

granite cast steel or aluminium profile |

|

| MS4 |

150 x 150 - 350 x 200 50 - 170 150 |

motorized hand driven |

granite cast steel or aluminium profile |

|

| MS5 |

200 x 200 - 420 x 300 150 - 300 |

motorized | granite granite and aluminium |

![]() Positioning Systems brochure download...

Positioning Systems brochure download...